How To Cut The Right Dip Tube Length For Pump Or Sprayer?

Misunderstandings, even simple ones, can cause big problems. Dip tube lengths are an area of packaging that can be wildly confusing. Most of the pump and sprayer manufacturers produce pumps with one standard dip tube length that is designed to be long so you can trim it to your needs. If you need help cutting the length of dip tubes – have no fear, follow the 3 steps to figure out how to cut the right dip tube length for your pump or sprayer:

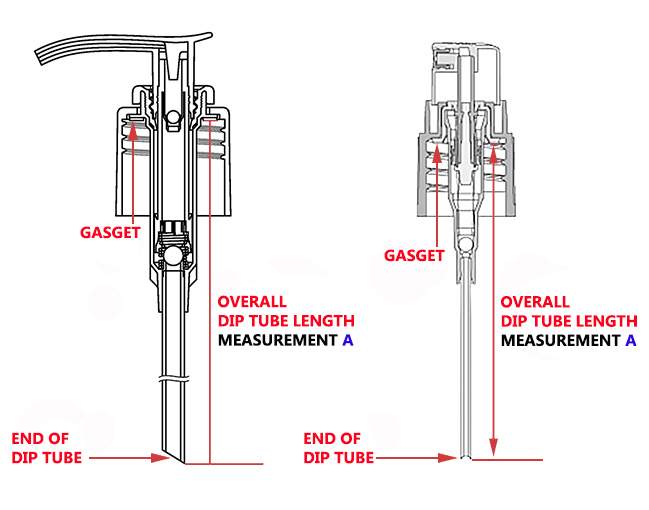

Step 1

Measuring the length from the gasket to the end of the dip tube. The number that you find will give you the overall dip tube length, let’s call this measurement A.

Step 2

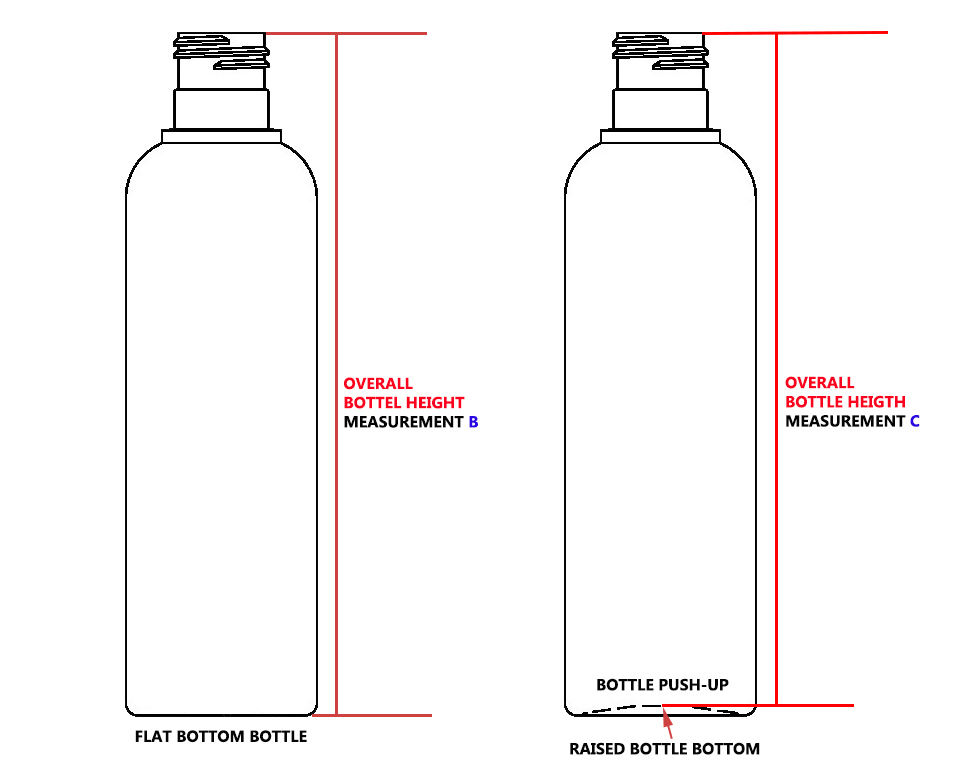

Measure the bottle your pump or sprayer goes in. You can do this by measuring from the top of the bottle, all the way to the bottom of the container. For bottles with a raised bottom, do this measuring from the top till the raised bottom.

How To Measure The Bottle Height Of Your Container

How To Measure The Bottle Height Of Your Container

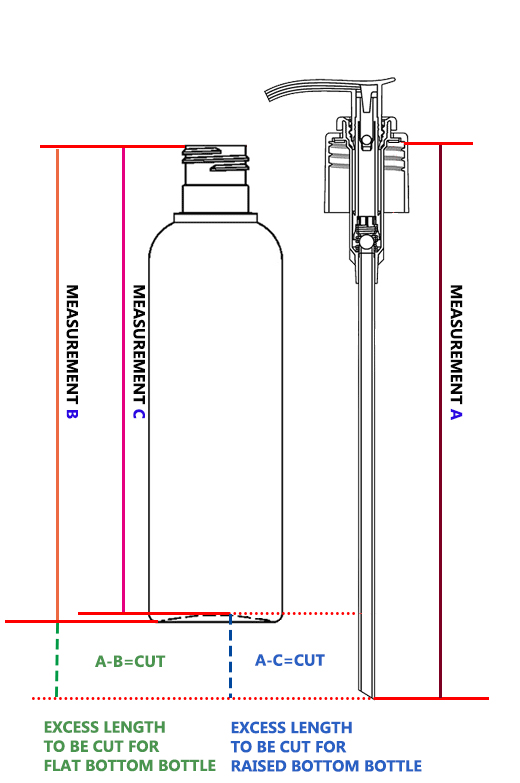

Step 3

Find out the length of the dip tube that needs to be cut, by simply calculate the difference between measurement A and B (flat bottom bottle)or A and C (raised bottom bottle).This is the excess length of the dip tube you don’t need.

Curving the tube to maximize the dispensing of product

There are two different ways that the dip tube can lay in the bottle. For most thinner dip tubes found mostly on sprayers, the tube should bend toward the container wall, maximizing the dispensing of the product. For thick dip tubes that most lotion pumps use, the tube can sit in the product with a slight gap from the bottom to give the product room to be dispensed out of the container.

If you are ordering pumps and sprayers as a special order from Knida, we will cut the dip tube for you, all you need to do is tell us the dip tube length you need or measure the bottle height of the container your pump or sprayer goes in( follow step 2). If you don’t want to do the grunt work, just send us the bottle, Let us cut the perfect dip tube length for you !